|

|

한길정공 제품소개 악세서리

Agitator Paint Mixer

240-100

- Item No. : AGITATOR

- Part No. : 240-100

- Air Motor : DAG-180SP

- HP : 1¼

- Revolution : 300~7,600rpm

- Max. Air Pressure : 6kgf/㎠

1AM

- HP : 1/3

- Standard Capacity : 20ℓ

- Application : Low-viscosity

2AM

- HP : 3/4

- Standard Capacity : 20~200ℓ

- Application : Medium-viscosity

4AM

- HP : 1½

- Standard Capacity : 20~200ℓ

- Application : Medium-viscosity

6AM

- HP : 4

- Standard Capacity : 100~200ℓ

- Application : High-viscosity

.jpg)

1AM(240-110)

- HP : 1/3

- Standard Capacity : 20ℓ

- Application : Low-viscosity

.jpg)

1AM(240-120)

- HP : 1/3

- Standard Capacity : 20ℓ

- Application : Low-viscosity

.jpg)

2AM(240-210)

- HP : 3/4

- Standard Capacity : 40ℓ

- Application : Medium-viscosity

.jpg)

2AM(240-220)

- HP : 3/4

- Standard Capacity : 40ℓ

- Application : Medium-viscosity

.jpg)

4AM(240-410)

- HP : 1½(1.12kw)

- Standard Capacity : 40ℓ

- Application : Medium-viscosity

.jpg)

4AM(240-420)

- HP : 1½(1.12kw)

- Standard Capacity : 40ℓ

- Application : Medium-viscosity

.jpg)

6AM(240-610)

- HP : 4(3kw)

- Standard Capacity : 200ℓ

- Application : High-viscosity

.jpg)

6AM(240-620)

- HP : 4(3kw)

- Standard Capacity : 200ℓ

- Application : High-viscosity

Agitator(Paint Mixer)

HK-AGT-850A

- 2-POST-RAM up & down manually

- 2 or 3 screw impeller

- Individual reverse rotation screws

- Convenience of labor

- For high viscosity coating

| Part No. (HK-AGT-850A) / 2-POST-RAM-TYPE |

| Air Motor |

GAST 6AM-NRV-22A |

| Motor Power |

5HP |

| Revolution |

30~600rpm |

| Dimension(L×W×H) |

60×64×130(175)㎝ |

| Weight |

150㎏ |

HK-AGT-550A

- 2-POST-RAM up & down manually

- 2 or 3 screw impeller

- Dual rotation screws

- Convenience of labor

- For high viscosity coating

| Part No. (HK-AGT-550A) / 2-POST-RAM-TYPE |

| Air Motor |

GAST 6AM-NRV-22A |

| Motor Power |

5HP |

| Revolution |

30~600rpm |

| Dimension(L×W×H) |

60×64×130(175)㎝ |

| Weight |

150㎏ |

Long Nozzle

Long Nozzle

| Part No. |

Length |

| 121-010 |

100㎜ |

| 121-020 |

200㎜ |

| 121-030 |

300㎜ |

| 121-040 |

400㎜ |

| 121-050 |

500㎜ |

Accessories

TIP FILTER TIP FILTER#60:110-060, #80:110-080, #100:110-100  TIP GUARD TIP GUARD747-201 .jpg) GUN NOZZLE(747) GUN NOZZLE(747)120-100  GUN SWIVEL GUN SWIVEL1/4" 130-000, 3/8" 130-100  MIX MANIFOLDER MIX MANIFOLDER2MM-100  OILER OILER731-308  PAINT-HOSE PAINT-HOSE1/4"(1W1B), 1/2"(1W2B), 3/8"(1W1B), 3/16"(1W1B), 3/16"(1W1B/1B)  SURGE TANK SURGE TANK220-100

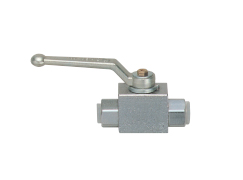

AIRLESS TIP AIRLESS TIP163-000 .jpg) TIP GUARD(F) TIP GUARD(F)747-202 .jpg) GUN NOZZLE(300) GUN NOZZLE(300)120-110  HOSE SWIVEL HOSE SWIVEL3/8"×3/8", 1/4"×3/8", 1/4"×1/4"  FLUID REGULATOR FLUID REGULATORHK-FPR-100  REGULATOR REGULATOR731-309  HIGH PRESSURE VALVE HIGH PRESSURE VALVE1/4", 3/8", 1/2", 3/4"  SWIVEL SURGE TANK SWIVEL SURGE TANK220-200

SWITCH TIP SWITCH TIPXHD-000  SWITCH TIP GUARD SWITCH TIP GUARDXHD  POLE-GUN NOZZLE POLE-GUN NOZZLE120-200  HOSE NIPPLE HOSE NIPPLE3/8"×3/8", 1/4"×3/8", 1/4"×1/4"  RETURN P/V RETURN P/V220-113  AIR FILTER AIR FILTER731-310  PUMP ADAPTER PUMP ADAPTER1/4" 220-110 3/8" 220-120  SWIVEL SURGE TANK SWIVEL SURGE TANK220-300

Fluid Heater

HK-HPFH 100 / HK-HPFH 200

- The optimum temperature control for high viscosity paint & solid coating

- Provides operating temperature range of 32~102 ℃

- Provides outstanding corrosion resistance and high heat conductivity and responsibility through aluminum body design

- Compatible with most paint available to inject pump

| Part No. |

HK-HPFH 100 |

HK-HPFH 200 |

Part No. |

HK-HPFH 100 |

HK-HPFH 200 |

| Rated Voltage |

220V |

440V |

Degree of Temperature Accuracy |

±1.8℃ |

±1.8℃ |

| Power Consumption |

3KW |

3KW |

| Rated Pressure |

500bar |

500bar |

Weight |

18㎏ |

18㎏ |

| Fluid Pipe Diameter |

10.4㎜ |

10.4㎜ |

|

|

|

Airless Pump Tester

100LT / 700BAR

- Removes residual paint inside the pump before an overhaul

- Checks normal conditions after overhauling the airless pump

- Checks the discharge pressure of the airless pump

- Checks the leaks of paint from the displacement pump

- Removes waste products generated by the overhauling of the pump

| Part No. (100LT/700BAR) |

| Dimension(L×W×H) |

85×57×117㎝ |

| Weight |

80㎏ |

Coating Thickness Measurement

MINITEST 650

This measuring instrument is widely used,

particularly for general purpose.

Measured values and statistics can be printed out by means of a portable printer

[ purchased separately ].

| Usage |

- Quick and accurate nondestructive coating thickness measurement

Features

- Practically small size

- Built-in function of statistical analysis function

- An improved keypad mold

- Improved operating system for accurate measurement

- Coating iron and metal with all kinds of nonmagnetic materials such as paint, enamel, chromium, zinc, etc.

- Improving the super hard materials of the probe

| Part No. (MINITEST 650) |

| Measuring Range |

TYPE F(Ferrous Metal) : 0~3,000 µ m / 120mils |

Display |

Display 4 digits(11㎜ / 0.44") |

TYPE N(Nonferrous Metal),

FN(Common Use) : 0~2,000 µ m / 80mils |

Measuring Unit |

Selectable µ m - mils |

| Calibration |

Standard, 1point, 2point |

| Measuring Accuracy |

±2 µ m(0.08mils) or ±2% |

Statistic |

x, s, n(Max. 9999), Min., Max. |

| Min. Curvature Radius |

Convex 5㎜ / 0.2", Concave 25㎜ / 1" |

Interface |

USB |

| Min. Area for Measurement |

ø 20㎜ / 0.8" |

Battery |

3 Micro AAA Battery(More than 10,000 measurements) |

| Dimension(L×W×H) |

Body 70×122×32㎜, Probe 15 dia.×62㎜ |

| Min. Base of Thickness |

0.5㎜ / 20mils(F), 50 µ m / 2mils(N) |

Temperature |

Body 0℃~50℃, Probe -10℃~70℃ |

|

|

|